Professional soundproofing with spray foam insulation in Roundup MT for quieter homes, offices, and buildings while improving comfort and energy efficiency.

Affordable Soundproofing with spray foam insulation in Roundup, MT is an effective solution for homeowners and property owners who want to reduce unwanted noise while also improving insulation performance. Whether noise comes from traffic, neighboring properties, mechanical equipment, or interior room-to-room transfer, spray foam insulation helps create quieter, more comfortable living and working spaces.

Unlike traditional insulation materials, spray foam expands to seal gaps and cracks that allow sound and air to pass through walls, ceilings, and floors. This dual benefit of sound control and energy efficiency makes spray foam insulation a popular choice in residential and commercial buildings across Roundup MT.

Understanding soundproofing with spray foam insulation

Spray foam insulation is applied as a liquid that expands and hardens into a dense, airtight barrier. This expansion allows it to fill voids, seams, and small openings that standard insulation often misses. Since sound frequently travels through air gaps and structural openings, sealing these areas significantly reduces noise transmission.

Soundproofing with spray foam insulation does not eliminate all noise but greatly minimizes sound movement by reducing vibration, blocking air pathways, and adding mass to building assemblies. It is especially effective when paired with other sound-reducing materials.

How spray foam insulation reduces noise

Spray foam insulation reduces sound by addressing the main ways noise travels through buildings.

Air sealing

Noise often moves through gaps around outlets, wiring, plumbing, and framing. Spray foam seals these pathways completely.

Sound absorption

Open-cell spray foam absorbs airborne sound waves, reducing echoes and interior noise.

Added density

Closed-cell spray foam increases wall and ceiling density, limiting sound vibration transfer.

Vibration control

By bonding to surfaces, spray foam reduces vibration that carries sound through structural components.

These combined effects make spray foam insulation a reliable option for sound improvement in many environments.

Areas where spray foam soundproofing is most effective

Soundproofing with spray foam insulation can be applied throughout a property depending on noise concerns.

Interior walls

Reduces sound transfer between bedrooms, offices, and living areas.

Ceilings and floors

Helps control noise from upper or lower levels of a building.

Exterior walls

Minimizes traffic noise, wind sounds, and outdoor disturbances.

Garages and workshops

Limits noise from tools, vehicles, and equipment entering living spaces.

Mechanical rooms

Dampens sounds from HVAC systems, water heaters, and utility equipment.

Sealing these areas improves both acoustic comfort and energy efficiency.

Types of spray foam used for soundproofing

Choosing the right type of spray foam insulation is important for effective sound control.

Open-cell spray foam

This lighter, softer foam excels at absorbing sound waves and reducing echo. It is commonly used for interior walls and ceilings where noise reduction is a priority.Reliable Soundproofing with Spray Foam Insulation in Roundup MT

Closed-cell spray foam

Denser and more rigid, closed-cell foam provides excellent air sealing and structural strength. While it absorbs less sound than open-cell foam, it still reduces noise by blocking air movement and vibration.

Professional installers often recommend a combination based on the space and noise source.

Spray foam soundproofing installation process

The installation process is designed to ensure maximum coverage and performance.

Initial evaluation

The contractor inspects the building, identifies noise sources, and determines the best application areas.

Preparation

Surfaces are cleared, and nearby items are protected. Access points may be created in finished walls if needed.

Application

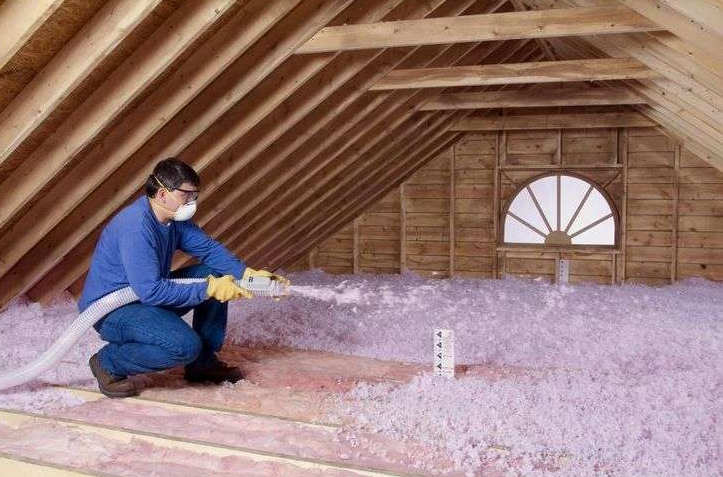

Spray foam is applied using specialized equipment, expanding to fill cavities and gaps.

Curing

The foam cures into a solid, airtight layer that blocks sound and air movement.

Finishing

Excess foam is trimmed, and surfaces are prepared for finishing materials if required.

Final inspection

The contractor verifies proper coverage and soundproofing effectiveness.

Professional installation ensures safety, accuracy, and long-term performance.

Cost factors for soundproofing with spray foam insulation

The cost of Top soundproofing with spray foam insulation in Roundup MT depends on several factors.

Size of the area

Larger spaces require more material and labor.

Type of foam

Open-cell foam is generally more affordable than closed-cell foam.

Accessibility

Finished walls and ceilings increase labor costs due to repairs and restoration.

Foam thickness

Greater thickness improves performance but raises material usage.

Additional soundproofing materials

Combining spray foam with drywall upgrades or acoustic systems increases overall cost.

Requesting detailed written estimates helps clarify pricing and project scope.

Choosing a spray foam insulation contractor in Roundup MT

Selecting the right contractor is essential for effective soundproofing.

Licensing and insurance

Ensure the contractor meets Montana licensing requirements and carries proper insurance.

Experience

Look for contractors with proven experience in spray foam soundproofing projects.

References and reviews

Customer feedback provides insight into quality and reliability.

Detailed estimates

Written proposals should outline materials, coverage areas, timeline, and warranties.

Safety standards

Professional contractors follow strict safety and ventilation protocols during installation.

A qualified contractor ensures your soundproofing investment delivers lasting results.

Maintenance and long-term performance

Spray foam insulation requires minimal maintenance once installed.

Occasional inspections

Check for visible gaps or damage over time.

Moisture monitoring

Ensure no leaks affect surrounding building materials.

Avoid unnecessary penetration

Drilling through insulated areas may reduce soundproofing effectiveness.

When properly installed, spray foam insulation maintains its performance for decades.

Frequently asked questions

Does spray foam insulation really reduce noise?

Yes, spray foam insulation reduces airborne noise by sealing gaps, absorbing sound, and limiting vibration transfer.

Which spray foam is better for soundproofing?

Open-cell spray foam is better for sound absorption, while closed-cell foam offers stronger air sealing and structural support.

Can spray foam be installed in existing walls?

Yes, professionals can apply or inject spray foam into existing walls with minimal disruption.

Is spray foam insulation safe indoors?

When installed by trained professionals and fully cured, spray foam insulation is safe for indoor use.

How long does soundproofing installation take?

Most residential projects take one to two days depending on size and accessibility.

Conclusion

Trusted Soundproofing with spray foam insulation in Roundup, MT provides an efficient and long-lasting way to reduce noise while improving energy efficiency and comfort. By sealing air gaps, adding density, and minimizing vibration, spray foam creates quieter indoor environments for homes and commercial properties alike. With professional installation and proper planning, this solution delivers durable acoustic improvement that enhances daily living and property value for years to come.